← Back to projects

Granuband Tire Machine

Making advanced industrial hardware usable in real operations

Situation

Granuband processes around 60 million tires per year for resale and recycling. To prepare for a future shortage of highly specialised inspectors, they invested in an advanced inspection machine. The machine combined German-built hardware with third-party software. It was originally designed for tire storage classification, not for Granuband’s more complex use case, which involves mostly worn-out tires.

Challenge

- Machine classifications didn’t match operational reality

- Frequent and unexplained machine failures

- No insight into why tires were rejected

- Strong dependency on a small group of highly trained specialists

- Misaligned expectations between Granuband, hardware, and software suppliers

What we did

We acted as Granuband’s technical partner and bridge between management, operations, and suppliers.

- Aligned strategy with management and operational reality on the floor

- Analysed how the machine, software, and classification filters actually worked

- Aligned suppliers and Granuband around realistic technical capabilities

- Improved and extended filter mechanisms using real inspection data

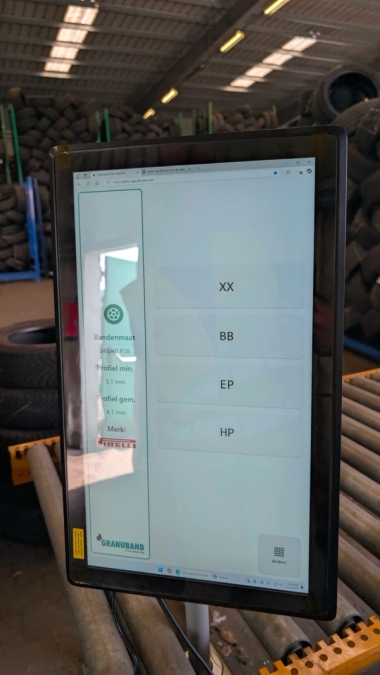

- Built an override interface for inspectors when visual nuance mattered

- Designed a guided inspection flow for faster onboarding of new staff

- Implemented a central data layer and management dashboard

Result

- Resolved frequent read issues, resulting in a high rate of successful machine reads

- Faster and easier onboarding of new personnel

- Reduced dependency on retiring specialists

- Clear insight into machine performance and return on investment

- A system that supports daily operations and aligns with Granuband’s growth strategy

Team

Yannick Caron

Digital Product Strategy & Frontend Development

Thomas de Jong

Solution Architecture & Backend Development

Remi Caron

CTO & CIO